Water Treatment

Home-Product-Water Treatment-Urban Sewage Treatment

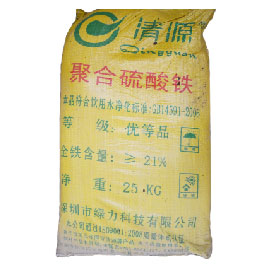

Polyferric sulfate

Shape appearance:

Yellow or reddish brown amorphous powder or granular solid

Yellow or reddish brown amorphous powder or granular solid

- Previous:

- Polyaluminum chloride

- Next:

- Lactic acid

Product Description

Product Usage:

Printing and dyeing wastewater treatment, replacing traditional low-molecular-weight iron and aluminum coagulants. Compared with traditional coagulants, the dosage is large, the coagulation efficiency is low, and the residual aluminum ions are easy to cause secondary pollution. The addition of polyferric sulfate The amount is about 150ppm, the amount is small, and the removal rate of COD and chroma is high. The best pH value condition is: 8.0. It can be used as coagulant and decomplex agent for electroplating sewage treatment. The complexes are mainly copper-ammonia complexes, which are stable in nature and have a pH of 11, making it difficult to directly undergo precipitation reaction with alkali, polyaluminum and other coagulants. It can also be used for water reuse. Papermaking wastewater treatment, replacing polyaluminum chloride, aluminum sulfate, etc., used as a coagulant, and can also be used for papermaking sludge dewatering.

Warehousing and transportation:

Avoid rain and hot sun during transportation. Be careful when loading and unloading to prevent damage to the package. In case of fire, water, sand, carbon dioxide fire extinguishers can be used to fight the fire. The packaging should be intact when shipping, and the loading should be secure. During transportation, ensure that the container does not leak, collapse, fall, or be damaged. Airtight operation, local exhaust. Operators must undergo special training and strictly abide by operating procedures. It is recommended that operators wear self-priming filter dust masks, chemical safety glasses, rubber acid and alkali resistant clothing, and rubber acid and alkali resistant gloves. Keep away from flammable and combustible materials. Avoid generating dust. Avoid contact with alkalis and alcohols. Pay particular attention to avoid contact with water. When handling, load and unload with care to prevent damage to packaging and containers. Equipped with leakage emergency treatment equipment. Empty containers may be harmful residues. Store in a cool, dry, well-ventilated warehouse. Keep away from fire and heat sources. The storage temperature should not exceed 30℃, and the relative humidity should be kept below 85%. The packaging must be sealed and kept away from moisture. It should be stored separately from easily (combustible) combustibles, reducing agents, active metals, alkalis, alcohols, etc., and avoid mixed storage. It should not be stored for a long time to avoid deterioration. The storage area should be equipped with suitable materials to contain the leakage.

Safety Precautions:

Closed operation, strengthen ventilation. Operators must undergo special training and strictly abide by operating procedures. It is recommended that operators wear self-priming filter dust masks, chemical safety glasses, anti-poison penetration overalls, and rubber gloves. Avoid generating dust. When handling, load and unload with care to prevent damage to packaging and containers. Equipped with leakage emergency treatment equipment. The operator wears labor protection equipment during use or transportation.

Printing and dyeing wastewater treatment, replacing traditional low-molecular-weight iron and aluminum coagulants. Compared with traditional coagulants, the dosage is large, the coagulation efficiency is low, and the residual aluminum ions are easy to cause secondary pollution. The addition of polyferric sulfate The amount is about 150ppm, the amount is small, and the removal rate of COD and chroma is high. The best pH value condition is: 8.0. It can be used as coagulant and decomplex agent for electroplating sewage treatment. The complexes are mainly copper-ammonia complexes, which are stable in nature and have a pH of 11, making it difficult to directly undergo precipitation reaction with alkali, polyaluminum and other coagulants. It can also be used for water reuse. Papermaking wastewater treatment, replacing polyaluminum chloride, aluminum sulfate, etc., used as a coagulant, and can also be used for papermaking sludge dewatering.

Warehousing and transportation:

Avoid rain and hot sun during transportation. Be careful when loading and unloading to prevent damage to the package. In case of fire, water, sand, carbon dioxide fire extinguishers can be used to fight the fire. The packaging should be intact when shipping, and the loading should be secure. During transportation, ensure that the container does not leak, collapse, fall, or be damaged. Airtight operation, local exhaust. Operators must undergo special training and strictly abide by operating procedures. It is recommended that operators wear self-priming filter dust masks, chemical safety glasses, rubber acid and alkali resistant clothing, and rubber acid and alkali resistant gloves. Keep away from flammable and combustible materials. Avoid generating dust. Avoid contact with alkalis and alcohols. Pay particular attention to avoid contact with water. When handling, load and unload with care to prevent damage to packaging and containers. Equipped with leakage emergency treatment equipment. Empty containers may be harmful residues. Store in a cool, dry, well-ventilated warehouse. Keep away from fire and heat sources. The storage temperature should not exceed 30℃, and the relative humidity should be kept below 85%. The packaging must be sealed and kept away from moisture. It should be stored separately from easily (combustible) combustibles, reducing agents, active metals, alkalis, alcohols, etc., and avoid mixed storage. It should not be stored for a long time to avoid deterioration. The storage area should be equipped with suitable materials to contain the leakage.

Safety Precautions:

Closed operation, strengthen ventilation. Operators must undergo special training and strictly abide by operating procedures. It is recommended that operators wear self-priming filter dust masks, chemical safety glasses, anti-poison penetration overalls, and rubber gloves. Avoid generating dust. When handling, load and unload with care to prevent damage to packaging and containers. Equipped with leakage emergency treatment equipment. The operator wears labor protection equipment during use or transportation.

13603024855

13603024855 Follow us

Follow us